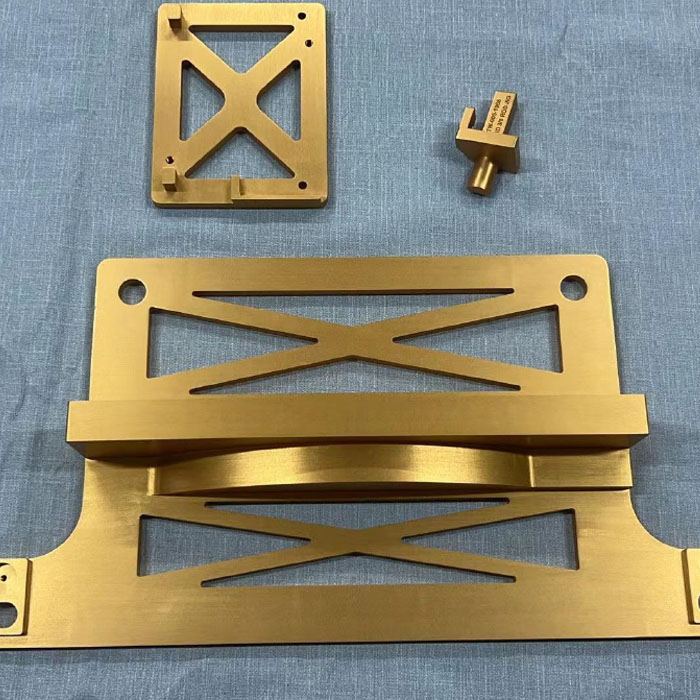

Custom Copper Part CNC Machining: The Perfect Fusion of Precision and Efficiency

Custom Copper Part CNC Machining: The Perfect Fusion of Precision and Efficiency

Explore High-Quality Custom Copper CNC Machining Services to Meet Your Specific Needs

In today’s competitive manufacturing industry, having a reliable CNC machining partner is crucial for ensuring product quality and reducing production cycles. We specialize in providing custom copper part CNC machining services to meet the high standards required for various industrial applications.

Why Choose Copper Part CNC Machining?

Copper is a material widely used in electrical, construction, industrial, and artistic fields. Known for its excellent electrical conductivity, thermal conductivity, and good machinability, choosing copper part CNC machining can bring the following advantages to your products:

High Electrical Conductivity: Copper is the second most conductive material after silver, making it ideal for electrical equipment and components.

Good Thermal Conductivity: Copper’s thermal conductivity makes it the perfect choice for heat sinks and heat exchangers.

Corrosion Resistance: Copper’s natural antibacterial properties make it very popular in medical and sanitary equipment.

Easy Machining: Copper’s softness and ductility make it easy to precisely machine with CNC machines.

Features of Our CNC Machining Services:

High Precision Machining: Our CNC machines are equipped with advanced control systems to ensure industry-leading machining accuracy.

Rapid Prototyping: We offer rapid prototyping services to help customers shorten the product development cycle.

Customized Design: We understand that each customer’s needs are unique, so we provide fully customized design solutions.

Material Optimization: We select the copper material that best suits your needs to ensure a balance of performance and cost-effectiveness.

Quality Assurance: Each finished copper part undergoes strict quality testing to ensure it meets your standards.

Our CNC Machining Process:

Requirement Analysis: Communicate with customers to understand specific needs and expected outcomes.

Design and Modeling: Based on requirements, perform 3D design and modeling to ensure the design meets machining requirements.

Programming: Professional programmers write CNC machining programs according to design drawings.

Machining: Copper parts are machined on high-precision CNC machines.

Quality Inspection: After machining, strict quality testing and testing are conducted.

Post-processing: Depending on the need, polishing, plating, or other surface treatments are performed.

Delivery: Deliver high-quality custom copper parts to customers on time.

Conclusion:

Choosing our custom copper part CNC machining services, you will gain unparalleled precision, efficiency, and professional support. We are committed to being your reliable partner in the field of copper machining, helping you achieve product innovation and enhance market competitiveness.

Contact Us:

Contact us immediately to get a free quote and professional consultation for custom copper part CNC machining. Let’s create your next innovative product together.

1. Rapid Prototyping

2. CNC Machined Parts

3. CNC Turning

4. Sheet Metal

5. Die Casting

6. Small to Large Batch Production with Various Quantities

7. CMM Inspection

8. Surface Treatment (Spray Painting, Screen Printing, Sandblasting, Electroplating, Anodizing, etc.)

1. Minimum Order Quantity: 1 Piece

2. 475 Available Materials

3. 21 Surface Treatment Options

4. We Have 100 Professional Employees.

5. 24-Hour Quotation for Prototypes

6. 4-24 Hour Quotation for Mass Production

7. 100% Full-Dimensional Inspection

8. Provision of CMM Inspection Reports, Heat Treatment Inspection Reports, and Surface Treatment Certificates

9. Many of Our Technicians Have Over 10 Years of Experience, Proficient in CNC 3-Axis, 4-Axis, and 5-Axis Programming, as Well as Various Molds.

10. If Needed, Our Engineering Team Can Provide Design Suggestions.

11. Our Engineering Team Can Offer the Most Reasonable and Economical Mass Production Solutions Based on Different Quantities.

12. If Required, We Can Deliver Assembled Products.

1. Robotics

2. Aircraft

3. Medical Devices

4. Automotive and Motorcycle

5. Machinery

6. Design Companies

7. Bicycles

8. Marine

9. Electronics

10. Scientific Equipment

11. Oil and Gas Control Systems

12. Signal Receiving Equipment

13. Optical Equipment

14. Beauty

15. Lighting

1. ISO9001 Certified, Laying a Solid Foundation for Product Quality.

2. Signing Non-Disclosure Agreements to Protect Customer Information.

3. Technicians Receive Annual Training to Continuously Improve Our Skills.

Propose project suggestions and optimize product structure.

Freely assemble.

Your quotation is very prompt; I enjoy working with you.

Your parts are truly excellent. We just received a large box today. Fantastic!