About Us

Dongguan Yuanfeng Precision Technology Co., Ltd.

Our company was founded in 1998 and is a professional enterprise specializing in the processing of high-end precision parts. We have modern production plants in Dongguan City and Shenzhen City, Guangdong Province, with a total production area of 6,000 square meters. The company's main business covers multiple fields of process processing such as precision CNC lathe through-feed machine/through-tool machine processing, CNC four-axis/five-axis machining centers, sheet metal manufacturing and precision stamping, and is committed to providing high-quality one-stop precision parts solutions for domestic and foreign customers.

We are proficient in processing various precision hardware parts, and our products are widely used in multiple industries. They mainly include: micro motor shafts, copper joints for household appliances, copper heads for atomizers, automotive hardware parts, mechanical equipment parts, computer, audio and electronic hardware accessory shells, electrical hardware parts, aluminum alloy mobile phone frames, high-end communication equipment parts, as well as related hardware parts for fishing gear, toys and locks. The processable materials cover a wide range of materials such as copper, iron, aluminum, plastic and stainless steel, and it has comprehensive precision manufacturing capabilities.

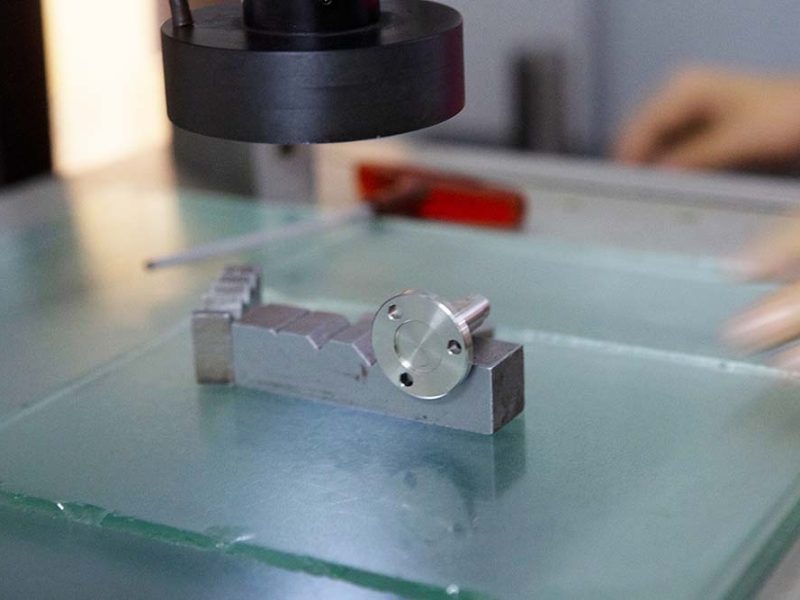

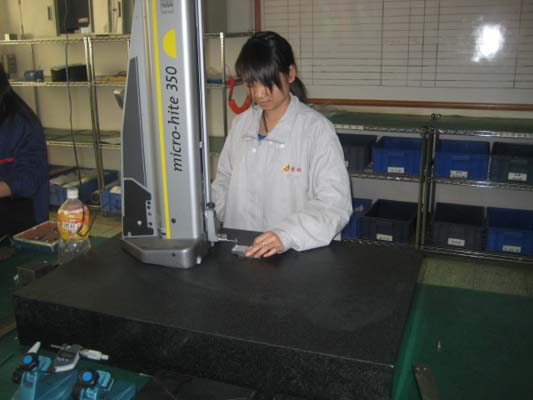

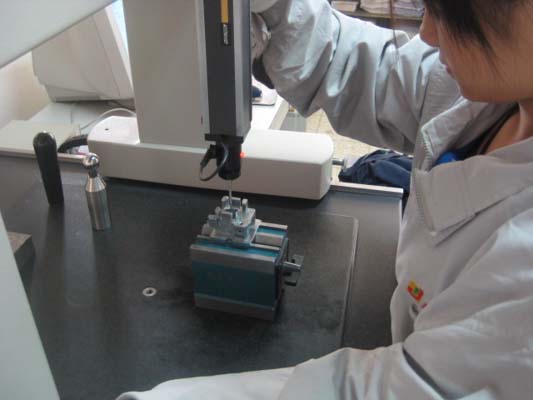

With advanced equipment, rigorous craftsmanship and strict ISO9001 quality control, we continuously provide customers with high-precision and high-quality products and services.

- There are 76 automatic lathes from Taiwan and Japan

- There are 38 CNC lathes

- 13 CNC numerical control turning and milling compound machines

- 15 CNC numerical control through-feed machines

- 45 CNC machining centers with four or five axes

- Over 200 Large and Small Secondary Processing Supporting Equipment

Automatic Lathe Equipment

CNC Lathe

Our CNC machines are equipped with automated robotic arms, significantly reducing labor costs and improving production efficiency. The equipment offers high machining accuracy and stable processing quality; it enables multi-axis linkage for machining complex-shaped parts; changes in processed parts generally only require modifications to the CNC program, saving production preparation time; the machines themselves are highly precise and rigid, allowing for optimal machining parameters and high productivity (typically 3–5 times that of conventional machines); a high degree of automation reduces labor intensity.