The Ultimate Guide to Sheet Metal Parts: Precision, Versatility, and Quality

Introduction

In the world of manufacturing, sheet metal parts play a crucial role in a wide range of applications, from automotive components to electronic enclosures. At Yuanfeng Precision Technology Co., Ltd. we specialize in high-quality sheet metal fabrication that meets the diverse needs of our clients. This guide will explore the benefits, processes, and applications of sheet metal parts, helping you understand why they are essential for your projects.

What are Sheet Metal Parts?

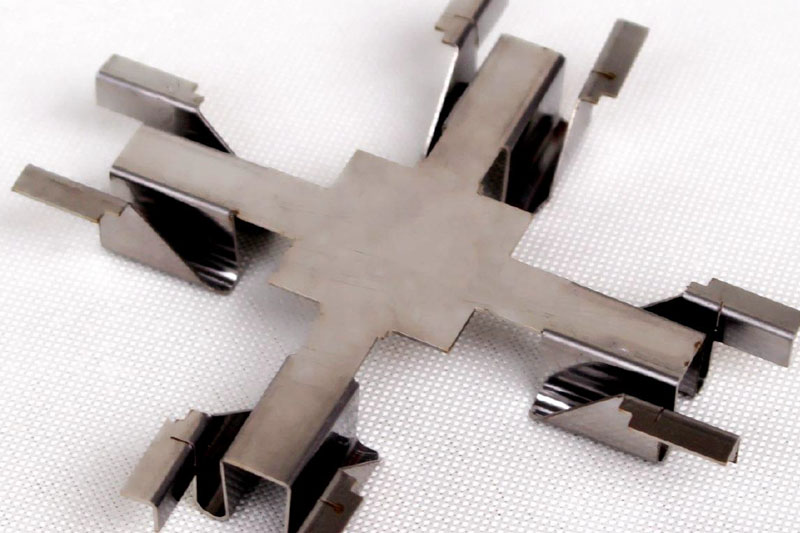

Sheet metal parts are components made from thin sheets of metal that are cut, bent, and shaped into various forms. These parts are known for their strength, durability, and versatility, making them ideal for a multitude of applications across different industries.

Advantages of Sheet Metal Fabrication

Cost-Effectiveness: Sheet metal fabrication is often more economical than other manufacturing methods, especially for high-volume production runs. The ability to produce multiple parts from a single sheet reduces material waste and lowers costs.

Versatility: Sheet metal can be fabricated into a wide variety of shapes and sizes, allowing for customization to meet specific project requirements. Whether you need brackets, enclosures, or complex assemblies, sheet metal can adapt to your needs.

Strength and Durability: Sheet metal parts are robust and can withstand harsh environments, making them suitable for applications in construction, automotive, and aerospace industries.

Finishing Options: A variety of finishing techniques, such as powder coating, anodizing, and painting, can enhance the appearance and corrosion resistance of sheet metal parts, providing both aesthetic and functional benefits.

Common Manufacturing Processes for Sheet Metal Parts

Laser Cutting: This process uses a high-powered laser to cut precise shapes and designs from sheet metal. It is ideal for intricate patterns and offers high accuracy with minimal material waste.

CNC Punching: CNC punching machines are used to create holes and shapes in sheet metal. This method is efficient for producing parts with multiple features quickly.

Bending and Forming: Using press brakes, sheet metal can be bent into various angles and shapes. This process is essential for creating components that require specific geometries.

Welding and Assembly: After individual parts are fabricated, they can be welded or assembled to create complex structures. This is crucial for applications that require multiple components to work together.

Applications of Sheet Metal Parts

Sheet metal parts are used in a variety of industries, including:

Automotive: Components such as chassis, brackets, and body panels.

Electronics: Enclosures for computers and other electronic devices.

Aerospace: Structural components that require lightweight yet strong materials.

Construction: HVAC systems, roofing, and siding materials.

Choosing the Right Sheet Metal Fabrication Partner

When selecting a sheet metal fabrication partner, consider the following factors:

Experience: Look for a manufacturer with a proven track record in producing high-quality sheet metal parts.

Capabilities: Ensure the company has the necessary equipment and expertise to meet your specific requirements.

Quality Assurance: Choose a partner that adheres to strict quality control measures and industry standards.

Customer Support: A responsive and knowledgeable team can help guide you through the design and manufacturing process.

Conclusion

At Yuanfeng Precision Technology Co., Ltd. we are committed to providing high-quality sheet metal parts tailored to your needs. Our advanced manufacturing processes, combined with our dedication to customer satisfaction, make us the ideal partner for your sheet metal fabrication projects. Contact us today to learn more about how we can help you achieve your manufacturing goals!

1. Rapid Prototyping

2. CNC Machined Parts

3. CNC Turning

4. Sheet Metal

5. Die Casting

6. Small to Large Batch Production with Various Quantities

7. CMM Inspection

8. Surface Treatment (Spray Painting, Screen Printing, Sandblasting, Electroplating, Anodizing, etc.)

1. Minimum Order Quantity: 1 Piece

2. 475 Available Materials

3. 21 Surface Treatment Options

4. We Have 100 Professional Employees.

5. 24-Hour Quotation for Prototypes

6. 4-24 Hour Quotation for Mass Production

7. 100% Full-Dimensional Inspection

8. Provision of CMM Inspection Reports, Heat Treatment Inspection Reports, and Surface Treatment Certificates

9. Many of Our Technicians Have Over 10 Years of Experience, Proficient in CNC 3-Axis, 4-Axis, and 5-Axis Programming, as Well as Various Molds.

10. If Needed, Our Engineering Team Can Provide Design Suggestions.

11. Our Engineering Team Can Offer the Most Reasonable and Economical Mass Production Solutions Based on Different Quantities.

12. If Required, We Can Deliver Assembled Products.

1. Robotics

2. Aircraft

3. Medical Devices

4. Automotive and Motorcycle

5. Machinery

6. Design Companies

7. Bicycles

8. Marine

9. Electronics

10. Scientific Equipment

11. Oil and Gas Control Systems

12. Signal Receiving Equipment

13. Optical Equipment

14. Beauty

15. Lighting

1. ISO9001 Certified, Laying a Solid Foundation for Product Quality.

2. Signing Non-Disclosure Agreements to Protect Customer Information.

3. Technicians Receive Annual Training to Continuously Improve Our Skills.

Propose project suggestions and optimize product structure.

Freely assemble.

Your quotation is very prompt; I enjoy working with you.

Your parts are truly excellent. We just received a large box today. Fantastic!