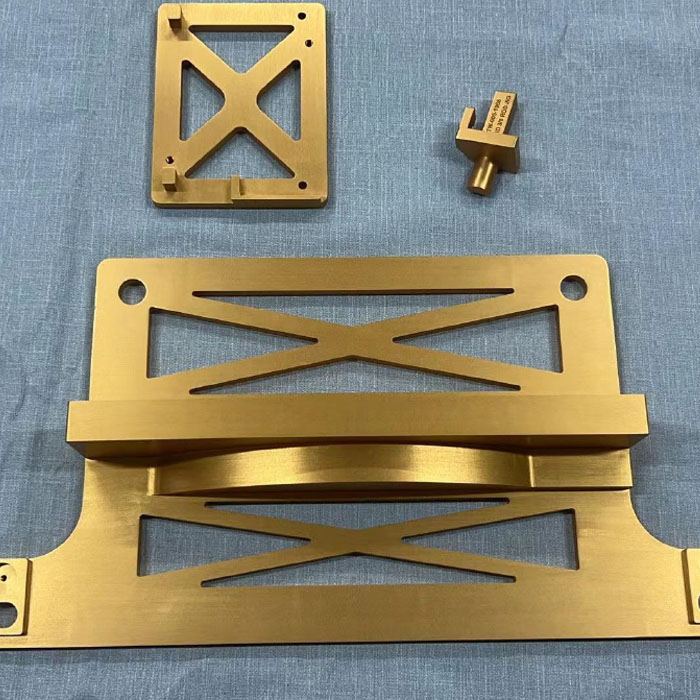

数控零件加工

数控加工-零件

Processing: CNC machine

材质:铜

表面:去毛刺

数控加工的精度和速度:现代制造业的基石

在当今快节奏的制造环境中,对高精度零件的需求比以往任何时候都大。CNC(计算机数控)加工技术已经彻底改变了复杂部件的生产,在满足这些需求方面起着关键作用。凭借其无与伦比的精度和速度,CNC加工站在现代制造工艺的最前沿,提供符合严格公差和行业标准的部件。

精准优势

精度是数控加工的标志。与手工加工不同,手工加工的最终产品的精度在很大程度上取决于操作员的技能,CNC加工由计算机控制系统控制。这些系统能够执行非常详细和复杂的指令,确保每一次切割、钻孔和表面光洁度都以微米级的精度执行。

在航空航天、汽车和医疗设备等行业中,持续实现如此严格的公差的能力至关重要,因为即使是最轻微的偏差也会产生严重的后果。例如,在航空航天部件的生产中,公差通常严格到0.001英寸。数控机床可以在这些参数范围内可靠地交付零件,确保安全性、性能和可靠性。

不妥协的速度

虽然精度至关重要,但在当今竞争激烈的制造业环境中,速度同样重要。数控加工通过自动化整个过程在这一领域表现出色,大大减少了生产零件所需的时间。现代数控机床可以以令人难以置信的高速度运行,在人工加工方法所需的一小部分时间内执行复杂的几何形状。

这种速度并不以准确性为代价。由于具有高速主轴、多轴功能和复杂的软件算法等先进功能,数控机床的设计即使在高速下也能保持精度。这些机器可以在一次设置中执行多个操作,减少了对额外夹具或重新定位的需求,从而最大限度地减少了停机时间并提高了吞吐量。

平衡公差与效率

数控加工的关键挑战之一是平衡严格公差的需求与快速生产周期的需求。实现超高精度通常需要较慢的进给速度和多道次,这会增加生产时间和成本。然而,数控技术已经发展到机器可以实时优化切削参数的地步,在精度和速度之间取得了理想的平衡。

例如,现代数控机床中的自适应控制系统监控切削条件并自动调整进给速度和主轴速度,以保持所需的公差,同时最大限度地减少周期时间。这不仅可以确保零件加工到精确的规格,还可以提高整体生产率。

Conclusion

CNC machining has set the standard for precision and speed in manufacturing, making it an indispensable tool for producing high-quality components. As the technology continues to evolve, we can expect even greater advancements in accuracy and efficiency, further solidifying CNC machining’s role as a cornerstone of modern manufacturing. Whether it’s producing critical aerospace components or intricate medical devices, CNC machining delivers the precision and speed necessary to meet the demands of today’s industries.

1. Rapid Prototyping

2. CNC Machined Parts

3. CNC Turning

4. Sheet Metal

5. Die Casting

6. Small to Large Batch Production with Various Quantities

7. CMM Inspection

8. Surface Treatment (Spray Painting, Screen Printing, Sandblasting, Electroplating, Anodizing, etc.)

1. Minimum Order Quantity: 1 Piece

2. 475 Available Materials

3. 21 Surface Treatment Options

4. We Have 100 Professional Employees.

5. 24-Hour Quotation for Prototypes

6. 4-24 Hour Quotation for Mass Production

7. 100% Full-Dimensional Inspection

8. Provision of CMM Inspection Reports, Heat Treatment Inspection Reports, and Surface Treatment Certificates

9. Many of Our Technicians Have Over 10 Years of Experience, Proficient in CNC 3-Axis, 4-Axis, and 5-Axis Programming, as Well as Various Molds.

10. If Needed, Our Engineering Team Can Provide Design Suggestions.

11. Our Engineering Team Can Offer the Most Reasonable and Economical Mass Production Solutions Based on Different Quantities.

12. If Required, We Can Deliver Assembled Products.

1. Robotics

2. Aircraft

3. Medical Devices

4. Automotive and Motorcycle

5. Machinery

6. Design Companies

7. Bicycles

8. Marine

9. Electronics

10. Scientific Equipment

11. Oil and Gas Control Systems

12. Signal Receiving Equipment

13. Optical Equipment

14. Beauty

15. Lighting

1. ISO9001 Certified, Laying a Solid Foundation for Product Quality.

2. Signing Non-Disclosure Agreements to Protect Customer Information.

3. Technicians Receive Annual Training to Continuously Improve Our Skills.

Propose project suggestions and optimize product structure.

Freely assemble.

Your quotation is very prompt; I enjoy working with you.

Your parts are truly excellent. We just received a large box today. Fantastic!